THERMOWELLS

TLSW1

Description

Thermowells serve as protective devices for the primary detecting elements, e.g. RTDs and thermocouples for temperature control, recording and indicating of various processes.

The thermowell is fabricated from SS316/L material as standard. Other materials are available upon request. Generally, the thermowell material chosen for a specific installation is governed by corrosion conditions to which the thermowell is exposed. In some instances, strength is a primary requirement while corrosion resistance is secondary.

The model TLSW1 is a general-purpose metal protection tube with threaded process and thermometer connection adaptor welded on.

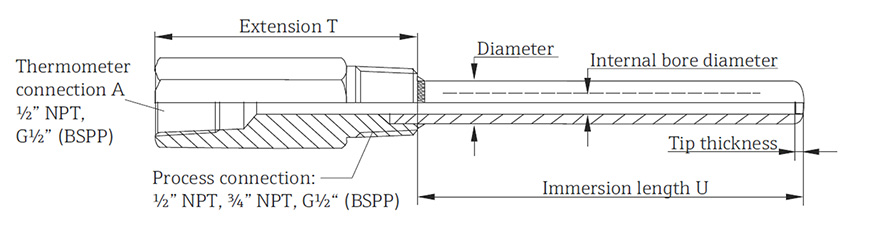

The distance from the hot end of the thermowell to the underside of the thread, or other connection, is identified as the immersion length U. For accuracy, the immersion length should be long enough to permit the entire temperature sensitive portion of the thermometer bulb, or the thermocouple element, to project into the temperature medium to be measured. Thermocouples have a short sensitive portion and can be used with thermowells having short immersion lengths. Resistance (RTD) thermometers have sensitive portions between 25 and 50 mm long.

Design

Technical Specifications

| Diameter | Measuring range limits | |||

| Operating conditions |

Maximum process pressure | 10mm | 5 MPa (50 bar) at 20 °C (68 °F) 3.3 MPa (33 bar) at 250 °C (482 °F) 2.4 MPa (24 bar) at 400 °C (752 °F) |

|

| 12mm | 7.5 MPa (75 bar) at 20 °C (68 °F) 5 MPa (50 bar) at 250 °C (482 °F) 3.5 MPa (35 bar) at 400 °C (752 °F) |

|||

| ¼” NB Sch. 40 | 7.5 MPa (75 bar) at 20 °C (68 °F) 5 MPa (50 bar) at 250 °C (482 °F) 3.5 MPa (35 bar) at 400 °C (752 °F) |

|||

| ¼” NB Sch. 80 | 10 MPa (100 bar) at 20 °C (68 °F) 6.7 MPa (67 bar) at 250 °C (482 °F) 4.6 MPa (46 bar) at 400 °C (752 °F) |

|||

| Maximum process temperature | Up to +600°C | |||